The Long Wheeled Carrying Protective Rifle Gun Hard Case is the ultimate solution for transporting and safeguarding your firearms with ease and confidence. Designed for durability, convenience, and maximum protection, this hard case is perfect for hunters, competitive shooters, law enforcement, and military personnel who need to transport long rifles or shotguns securely and comfortably.

The Case combines superior protection, portability, and convenience, making it the ideal choice for transporting your firearms safely and securely. Whether you’re heading to the range, the field, or storing your firearms, this case ensures your gear arrives in perfect condition every time.

Ideal For:

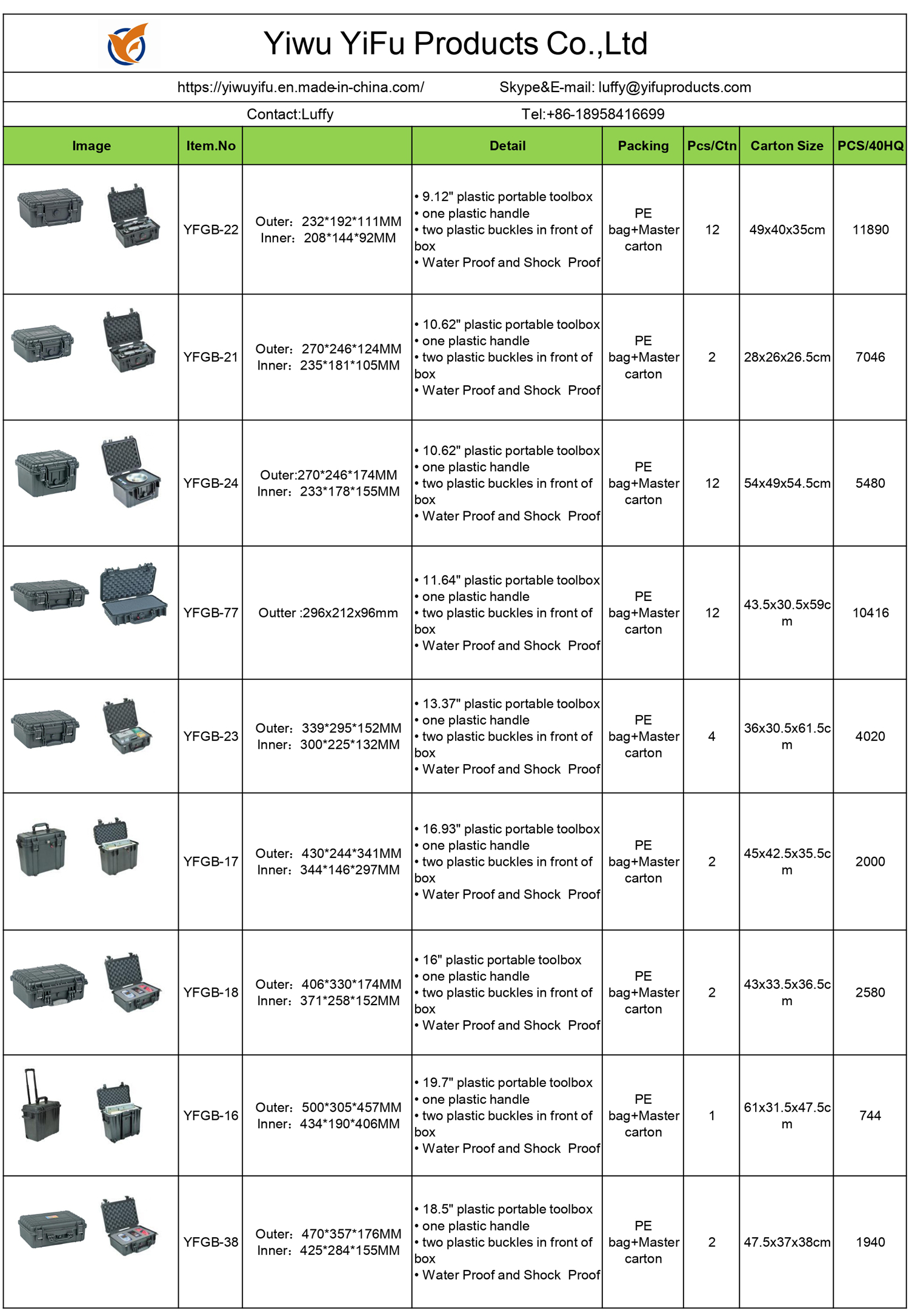

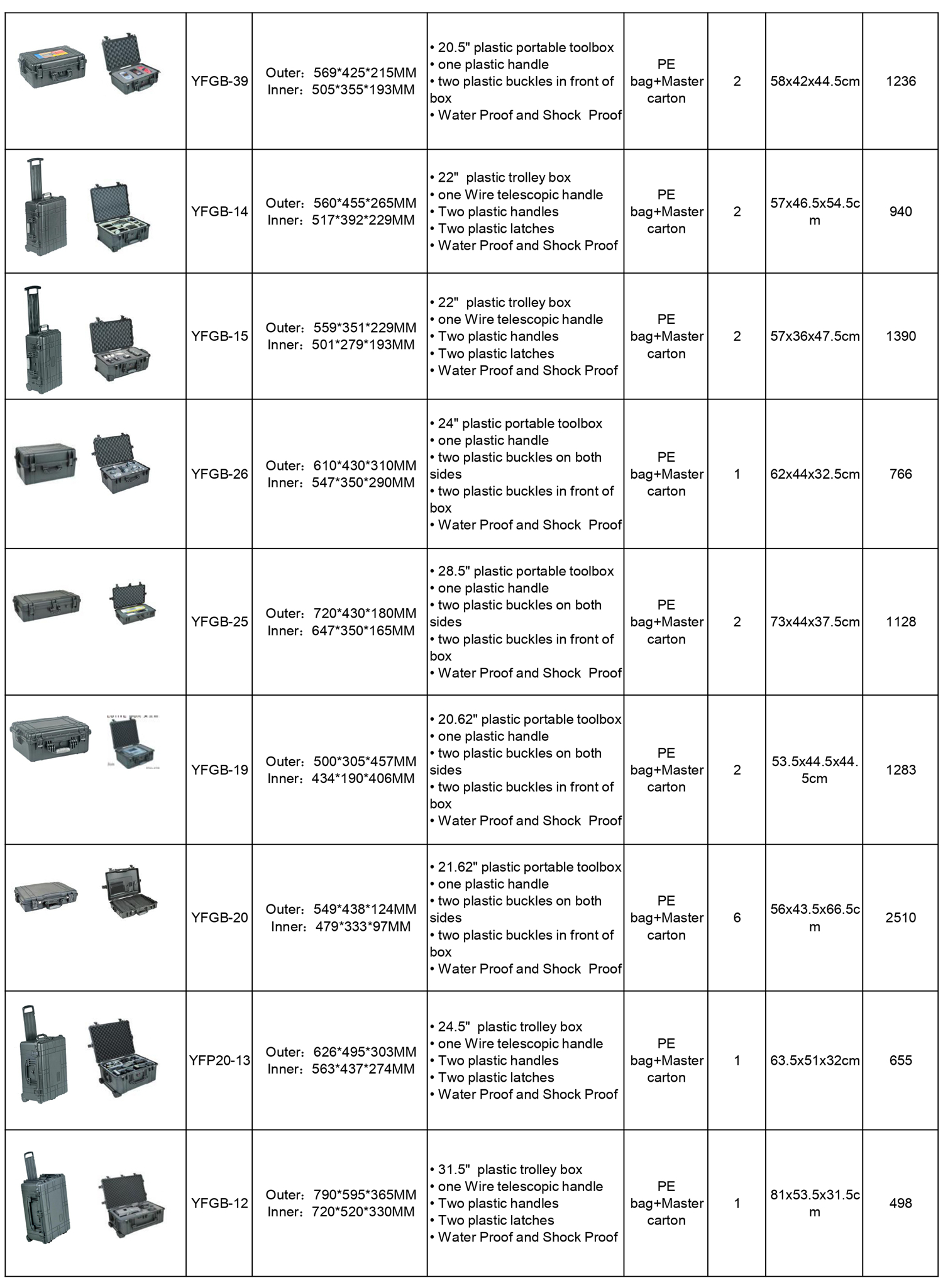

| Product Name | Wheeled Waterproof Protective Hard Plastic Case, Fit for Camera, Equipments, Lens,Drones, Military… |

| Model Number | YF-S1378 |

| Brand | IFSTAR |

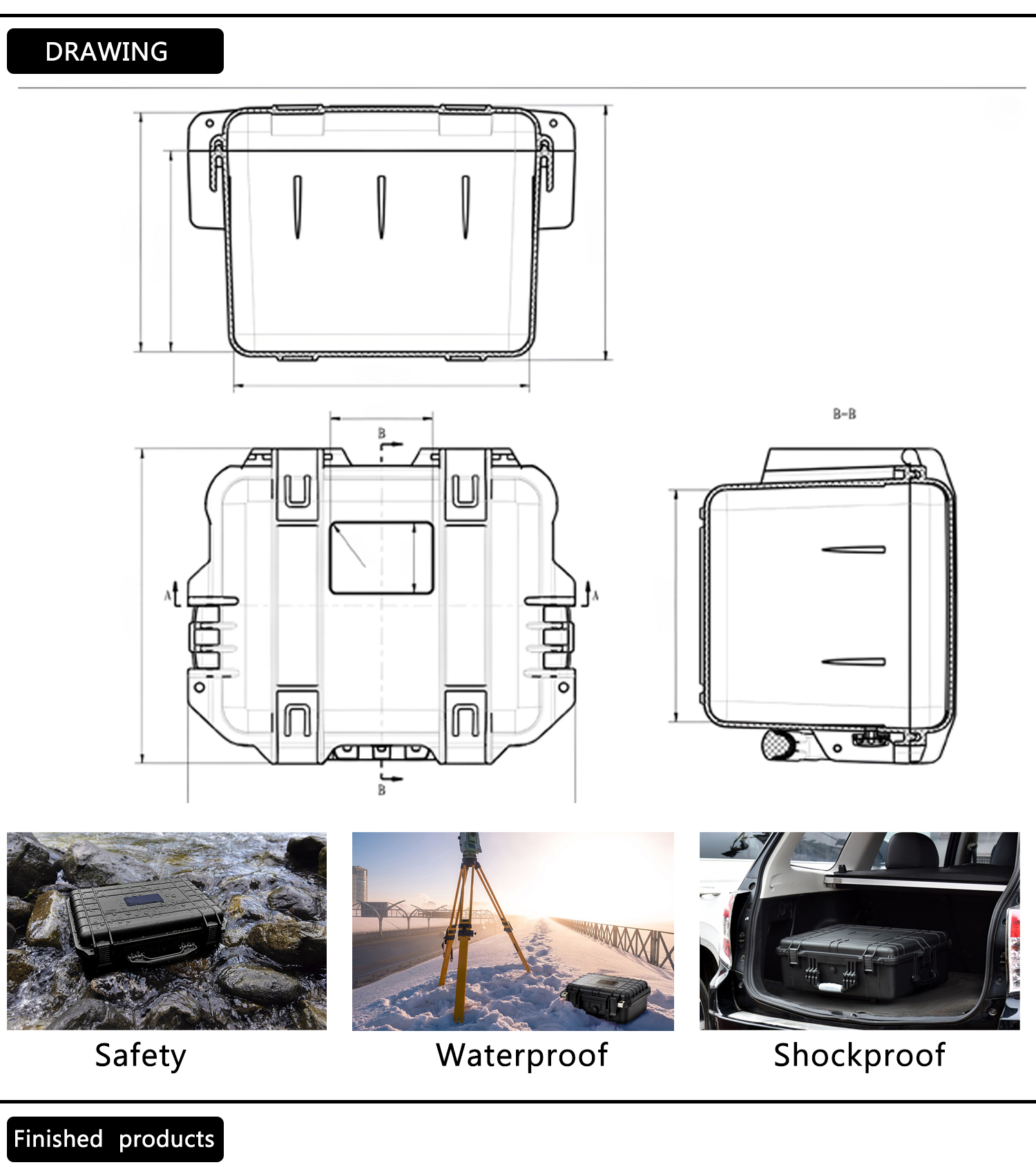

| Size | Exterior dimension: 1378*383*175MM , interior dimension: 1300*320*140MM, Depth:55+85MM |

| Material | PP |

| Type | Plastic carrying case |

| Color | Black/ white/ orange/ yellow/ Pantone color/ water transfer printing |

| Foam | Pre-cut/ EVA/ EPE/ PU / XPE/ custom |

| Logo Type | Rubber/Silk screen/PVC stick/Embossed/Custom |

| Surface | Matte finish |

| Feature | Hard, Waterproof, Shockproof, Durable, Portable |

| Certificate | CE, RoHS, BSCI, REACH |

| Operating Temperature | -25℃ to 120℃ |

| Support | Custom color/foam/logo/mold/organizer/panel |

| Usage | Tools, Equipment,Construction Gear, Sitework Acc. Storage/Carry, Government bidding projects |

| Place of Origin | Zhejiang, China |

| Brand: IFSTAR Part NO: YF-S1378 |

| Inner Size: 1300*320*140MM Outer Size: 1378*383*175MM |

| Net Weight: 10.8KG Protective Class: IP67 Shock resistance: IK08 |

| Accessory: Foam, lock, handle Material: Engineering plastic(PP) |

| Temperature: work temperature -25°c to 90°c, short term -40°c to 110 °c |

| Widely used in different field, like outdoor photography, field investigation, scientific exploration, fishing, police, army, expedition, etc. |

FAQ:

Q1:Are you a Factory or trading company?

Q2:How do you control the quality of your products?

We conduct strict inspections for every order that is about to leave the factory!Our factory has gained ISO9001:2015 and BSCI certificates.

Q3:Can you provide me your catalogue?

We have thousands of products, and every month we will make out many new items, so updating is very fast. Could you please provide us your request so we can recommend to you accordingly?

Q4:What is your advantage ?

1) We have a professional team with strong executive ability.

2) In time delivery.

3) Stable high-quality, all our products are with whole inspection.

4) Large productivity.

5) Having well-equipped workshop.

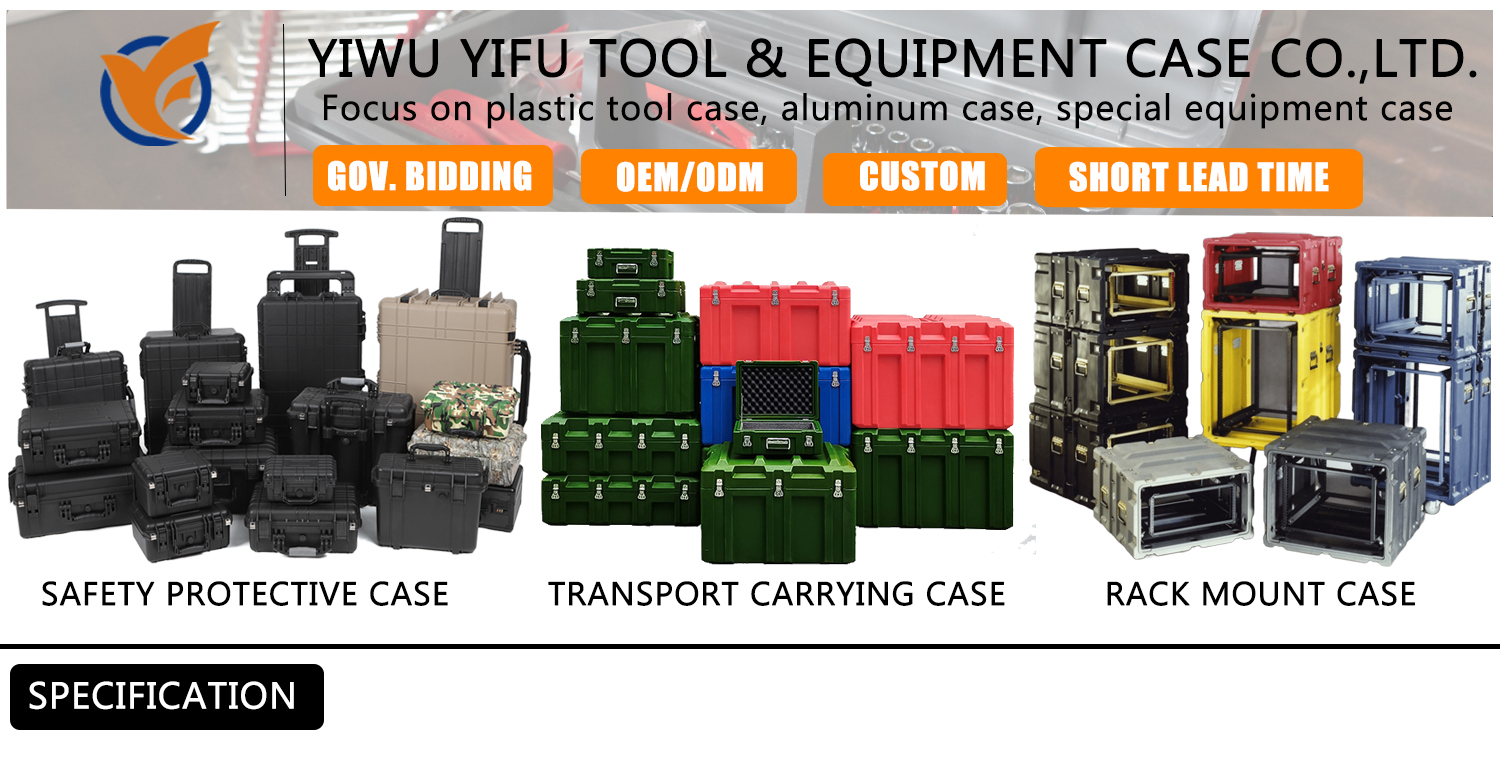

Yiwu Yifu Products was established in 2009 and headquartered in Yiwu City, Zhejiang Province, China. With the best advantage of convenient transportation, professional international trading and products experiences. We specialized in tool box, waterproof protective case, fishing box and tool kit by material of PP/ABS/Aluminium. We have a variety of advanced equipment and more than 60 experienced professional employees. We have more than 100 molds in R&D and cooperation, also are able to develop and process various products bases on customers’ requirements. Our company had undertaken many government bidding projects. All form of inquiries(OEM&customized services) will be appreciated and fulfilled by us here.

We are specialized in tool box, waterproof protective case, fishing box and tool kit by material of PP/ABS/Aluminium. We have a variety of advanced equipment and more than 60 experienced professional employees.

We have efficient production capacity, support 24-72 hours fast sample, 15 days fast delivery, we can also make urgent orders if needed and make every effort to meet the various requirements of customers.

Based on the business philosophy of “People-oriented, target management, pursuit of excellence, equality and win-win”. Our company have won the praise and trust of customers. The products are sold well all around the world like North & South America, Europe, Africa ect.

We have attended Canton Fair many times, and met many lovely customers there. We are looking forward to meeting our new friends.

At here, it’s all about giving the clients thebest quality products.

Welcome to IFSTAR! Looking forward to long-term business relationships with clients all over the world.